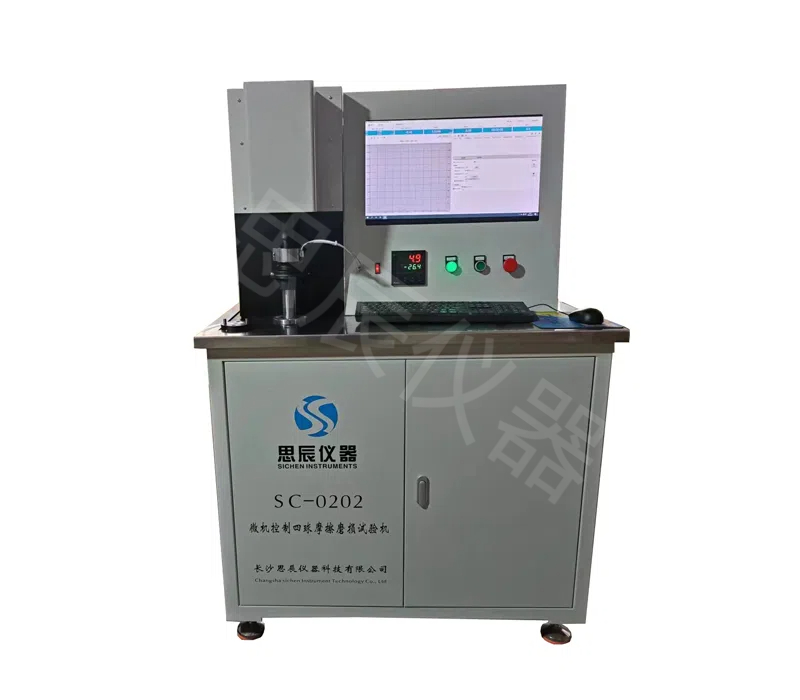

- Lubricating oil/detection and analysis category

This instrument is mainly used in the form of sliding friction to distinguish the low, medium, and high extreme pressure performance of lubricants under extremely high point contact pressure conditions, including three indicators: maximum non card bite load PB, sintering load PD, and comprehensive wear value ZMZ. This machine can also be used for testing the anti-wear performance of lubricants. If special accessories are used, end face wear tests can also be conducted to determine the friction coefficient of friction pairs. This machine is mainly suitable for industries such as petrochemicals, steel metallurgy, transportation, and higher education institutions. Reference standards: GB/T2611-2007 General Technical Requirements for Testing Machines GB/T12583-98 Lubricant Extreme Pressure Performance Determination Method (Four Ball Machine Method), GB3142-82 Lubricant Load Capacity Determination Method (Four Ball Machine Method), SH/T0189-92 Lubricant Anti Wear Performance Determination Method (Four Ball Machine Method), SH/T0202-92 Lubricant Extreme Pressure Performance Determination Method (Four Ball Machine Method), SH/T0204-92 Lubricant Anti Wear Performance Determination Method (Four Ball Machine Method), ASTM D2625, ASTM D5183, ASTM D2266, ASTM D4172, etc.

1. Test force range: 40N~10000N

2. Maximum allowable variation of test force: ± 0.3% FN

3. Friction measurement range (N): 0-300

4. Accuracy of friction force indication: Within the range of 10N-300N, the relative error of indication shall not exceed ± 2%, and the relative error of indication repeatability shall not exceed 2%.

5. Spindle speed range (r/min): 1-2000

6. Spindle speed error (r/min): ± 5

7. Working temperature range of heater (℃): Room temperature~260

8. Temperature control accuracy (℃): ± 2

9. Time setting range (s or min): 1 to 9999

10. Range of RPM settings: 1 to 9999999

11. Standard test steel ball diameter (mm): φ 12.7

12. Dimensions: 1000mm × 600mm × 1600mm

13. Net weight of testing machine (kg): approximately 300

1. The loading is composed of precision ball screws, linear motion ball bearings, and force shafts, with low friction and minimal impact on the accuracy of the test force.

2. The test force sensor adopts a load sensor installed between the force shaft and the piston, which is sensitive to changes in the test force and has high accuracy in indicating the test force

3. The experimental force is controlled by servo motors, which have fast response to changes, high control accuracy, and minimal impact on the experimental results.

4. The measurement and control software is based on the Windows operating system and supports XP, Win7, Win8, and Win10 systems

5. The application of experimental force is controlled by a servo system, ensuring smooth and reliable application. The magnitude of the experimental force can be set by the operator on the computer interface.

6. The parameters such as spindle speed, rotation speed, loading force, and test time are all controlled by a computer, and real-time data such as friction force, friction coefficient, and test temperature are displayed. The test data can be collected and saved in real time, and the friction force can be plotted

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved