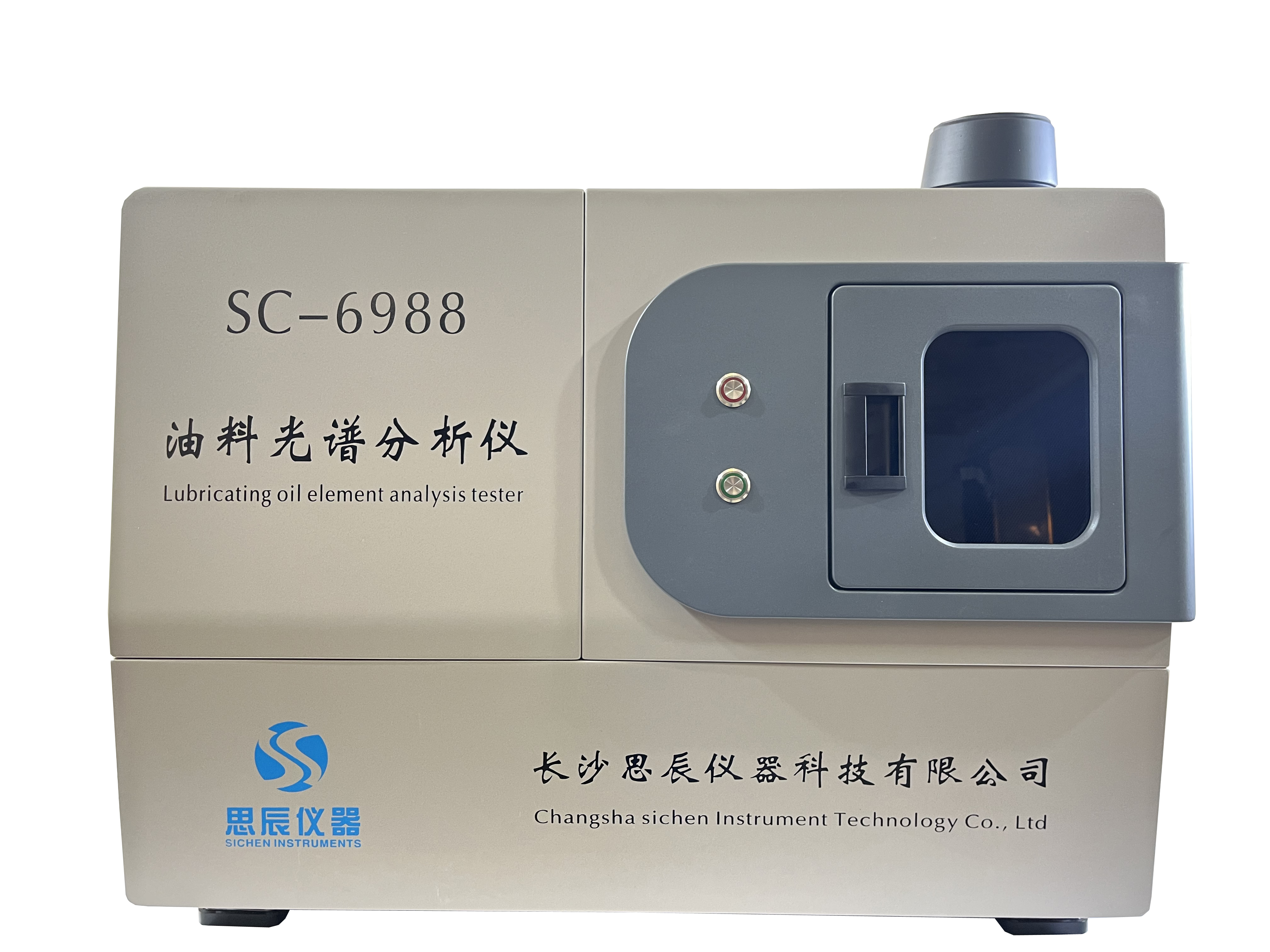

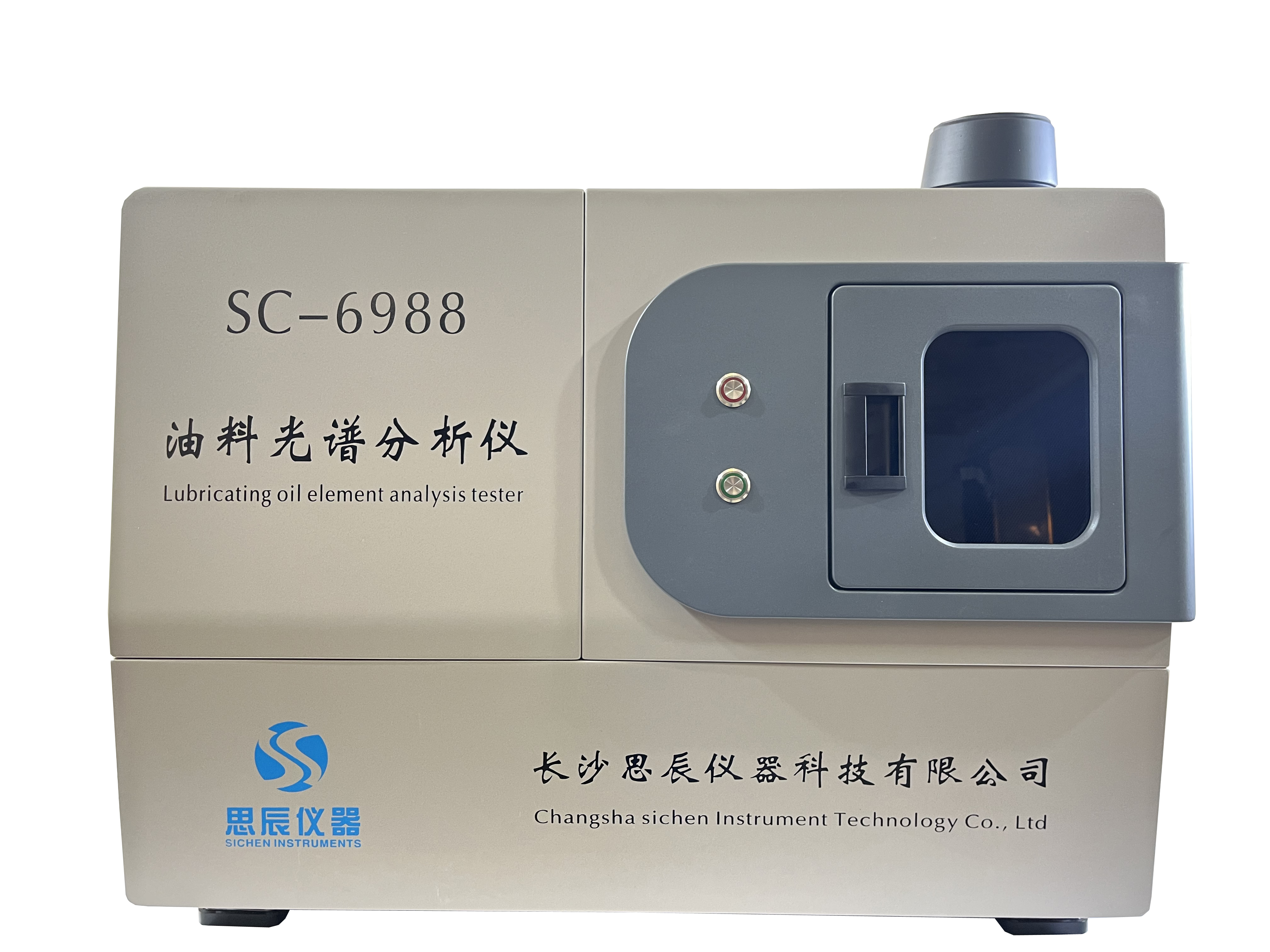

- Lubricating oil/detection and analysis category

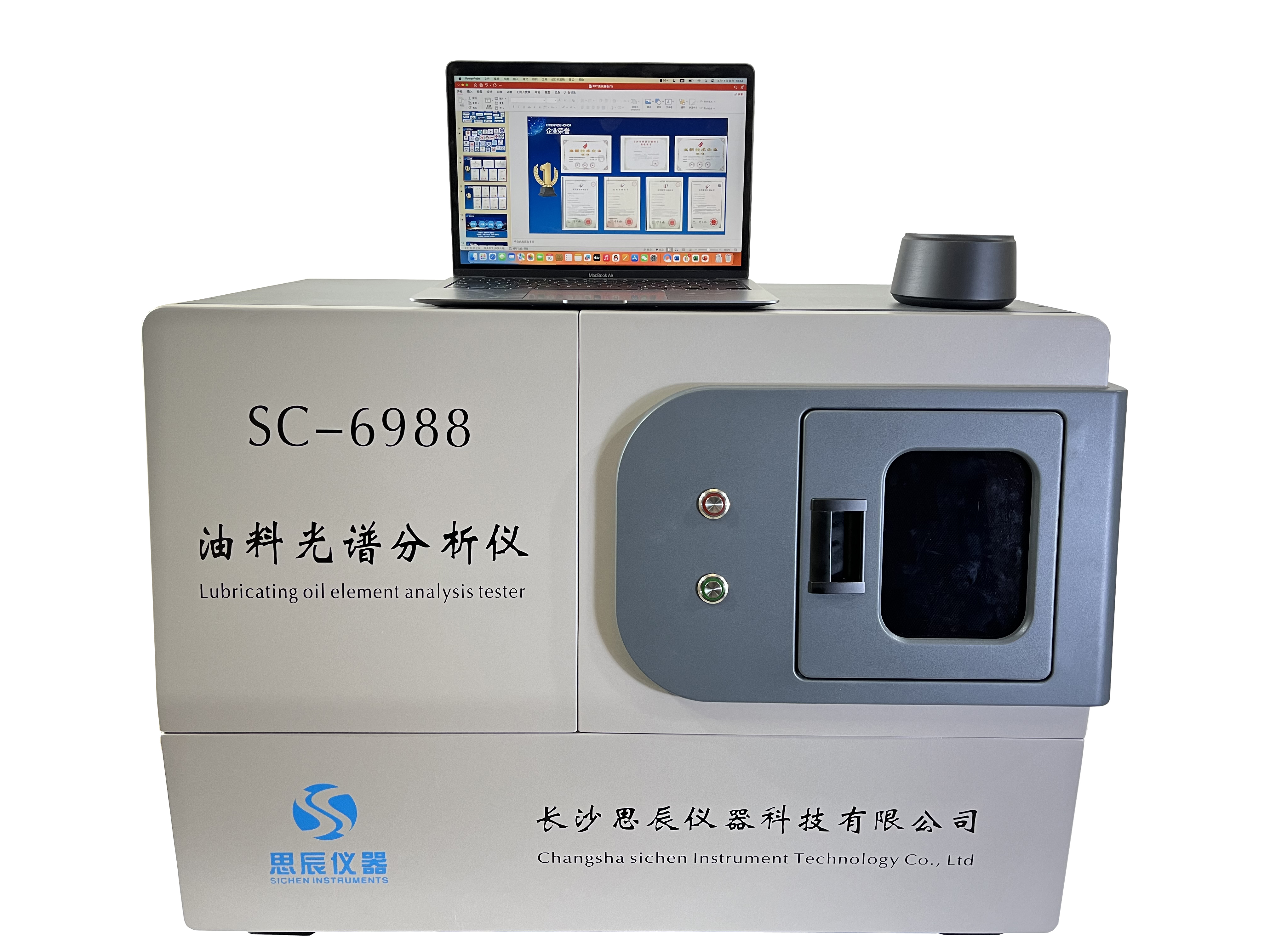

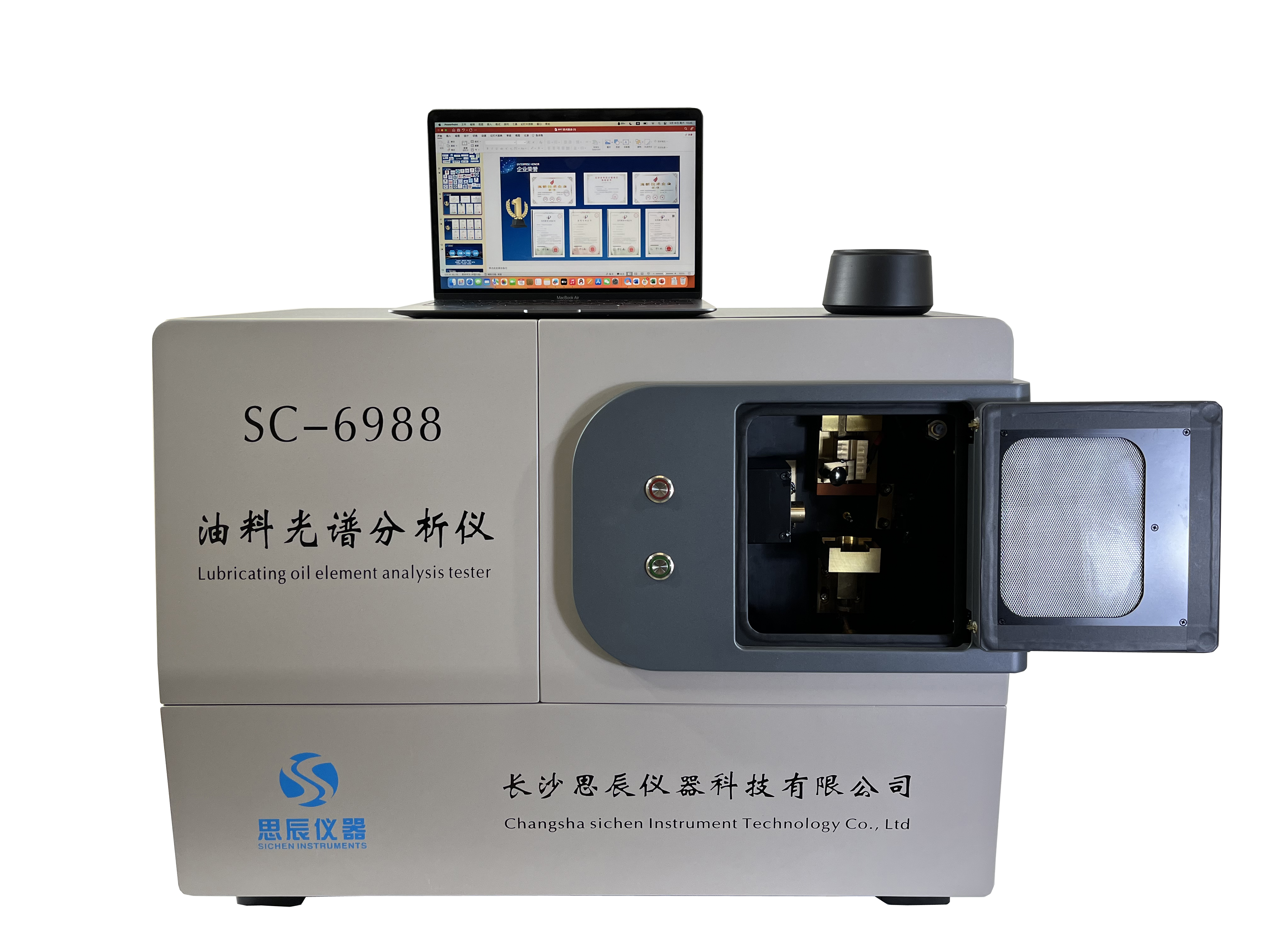

This instrument can accurately determine the elemental composition and concentration of trace metal abrasive particles and their additives in oil samples, thereby obtaining information on the wear status, lubrication status, and contamination status of lubricating oil. Through statistical analysis and trend analysis of historical data (detection results and equipment maintenance records), it comprehensively grasps the wear trend and lubrication status changes of equipment. This instrument meets the standard ASTM D6595 method (Standard Method for Determining Wear Metals and Pollutants in Lubricating Oil or Hydraulic Fluid by Rotating Disc Electrode Atomic Emission Spectroscopy) ASTM D6728 "Standard Test Method for Determining Pollutants in Gas Turbine and Diesel Engine Fuel by Rotating Disc Electrode Atomic Emission Spectroscopy" NB/SH/T 0865 National Energy Administration standard "Determination of Wear Metals and Pollutant Elements in Lubricating Oil by Rotating Disc Electrode Atomic Emission Spectroscopy" SN/T 1652 National Inspection and Quarantine Administration Import and Export Industry Standard "Detection Method for Pollutants in Gas Turbine and Diesel Engine Fuel Oil by Rotating Disc Electrode Atomic Emission Spectroscopy" DL/T 1550 National Energy Administration Power Industry Standard "Determination of Metal Copper and Iron Content in Mineral Insulated Oil by Rotating Disc Electrode Atomic Emission Spectroscopy" Electrode Emission Spectroscopy. This instrument is designed and optimized for performance using the latest CCD optical system and the durable and highly reliable rotating disk electrode technology (RDE). Quantitative analysis of small particles dissolved or suspended in oil is simple and easy to operate, with high testing reliability and durability. It can quickly detect the content of metal abrasive particles, pollutants, and additive elements in lubricating oil, and is suitable for commercial and military oil monitoring laboratories.

1. Power requirements: 220V ± 10%, 50Hz AC power supply;

2. Power consumption: ≤ 1kW;

3. Environmental adaptability: meets the requirements of Level 4 environmental adaptability in accordance with the national military standard GJB 3947A-2009, Section 3.8;

4. Electromagnetic compatibility: in accordance with the provisions of Article 3.9.1 of the National Military Standard GJB 3947A-2009;

5. Reliability: MTBF ≥ 8000h;

6. Maintainability: MTTR ≤ 4h (using whole piece replacement method);

7. Continuous working time ≥ 4 hours;

8. Dimensions: ≤ 1040 * 600 * 500mm;

9. Packaging size: ≤ 1300 * 700 * 700mm;

10. Wavelength range: 200nm to 810nm;

11. Detection range: 0mg/kg to 900mg/kg or 10mg/kg to 10000mg/kg, meeting ASTM D6595 standard;

12. Detection elements: 24 types Aluminum (Al) Barium (Ba) Boron (B) Cadmium (Cd) Calcium (Ca) Chromium (Cr) Copper (Cu) Iron (Fe) Lead (Pb) Magnesium (Mg) Manganese (Mn) Molybdenum (Mo) Nickel (Ni) Phosphorus (P) Silicon (Si) Silver (Ag) Sodium (Na) Tin (Sn) Titanium (Ti) Vanadium (v) Zinc (Zn) Potassium (K) Lithium (Li) Antimony (Sb);

13. Testing repeatability (standard deviation of test values) meets the requirements of ASTM D6595-00 (2011) standard;

14. Detection accuracy (error between average and standard values): ± 2mg/kg (0mg/kg~10mg/kg) ± 10% (10mg/kg~900mg/kg)

15. Instrument consistency: The percentage difference shall not exceed 15% (50mg/kg standard oil);

16. High performance holographic diffraction grating with grating lines of 2700L/mm

17. Roland circle focal length: 500mm-750mm

18. Optical resolution 0.006nm

19. High performance spark light source: ignition voltage 14000V, bidirectional excitation

20. Real time data collection 128 times/second

1. Measurement of wear elements in lubricating oil, which can determine 24 metal elements Aluminum (Al) Barium (Ba) Boron (B) Cadmium (Cd) Calcium (Ca) Chromium (Cr) Copper (Cu) Iron (Fe) Lead (Pb) Magnesium (Mg) Manganese (Mn) Molybdenum (Mo) Nickel (Ni) Phosphorus (P) Silicon (Si) Silver (Ag) Sodium (Na) Tin (Sn) Titanium (Ti) Vanadium (v) Zinc (Zn) Potassium (K) Lithium (Li) Antimony (Sb)

2. Inject the oil directly, with a sample detection time of less than 1 minute, and measure once to obtain the result;

3. Equipped with a voltage regulator, suitable for 220V, 50Hz conventional AC power supply;

4. The overall structural light chamber has good seismic resistance and transportability;

5. Dual independent constant temperature between the light chamber and the host: effectively suitable for situations where the ambient temperature is too high or too low;

6. Safety monitoring function: It has monitoring and warning functions such as whether the electrode of the monitoring disk is in place, whether the electrode of the rod is in place, whether the electrode spacing is correct, whether the oil sample is on the sample rack, and whether the excitation chamber door is closed. It also has a 15A power automatic fuse function;

7. Software automation function: It has the function of automatically calculating mean, standard deviation, and relative standard deviation; Equipped with automatic optical spectral line correction (automatic tracing) function; Capable of automatic curve fitting and standardized calibration; Can store and read data; Capable of statistical analysis and trend analysis, exporting detection results through USB data collection; The software can set threshold and over limit alarm function (color change);

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved