- Lubricating oil/detection and analysis category

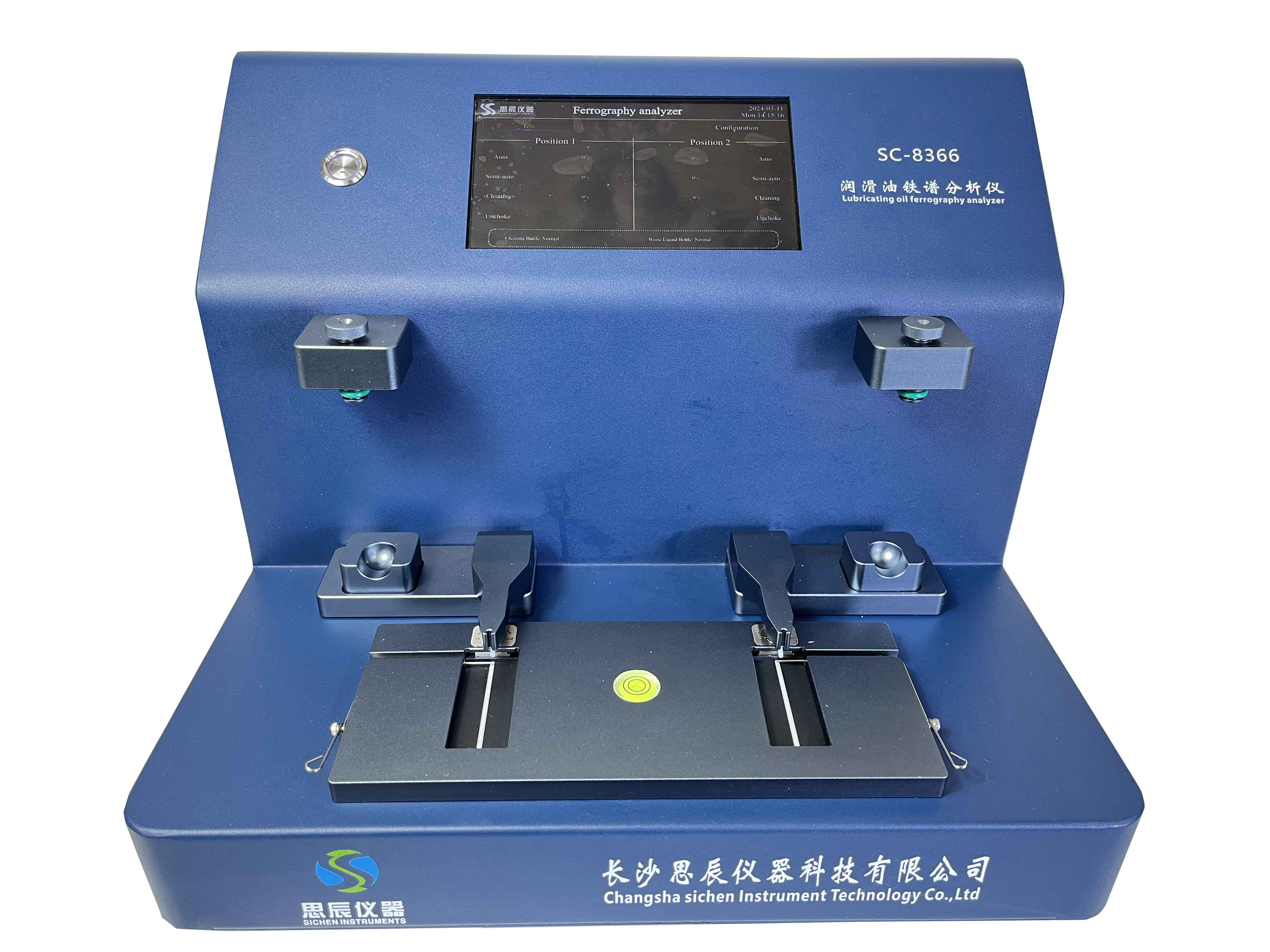

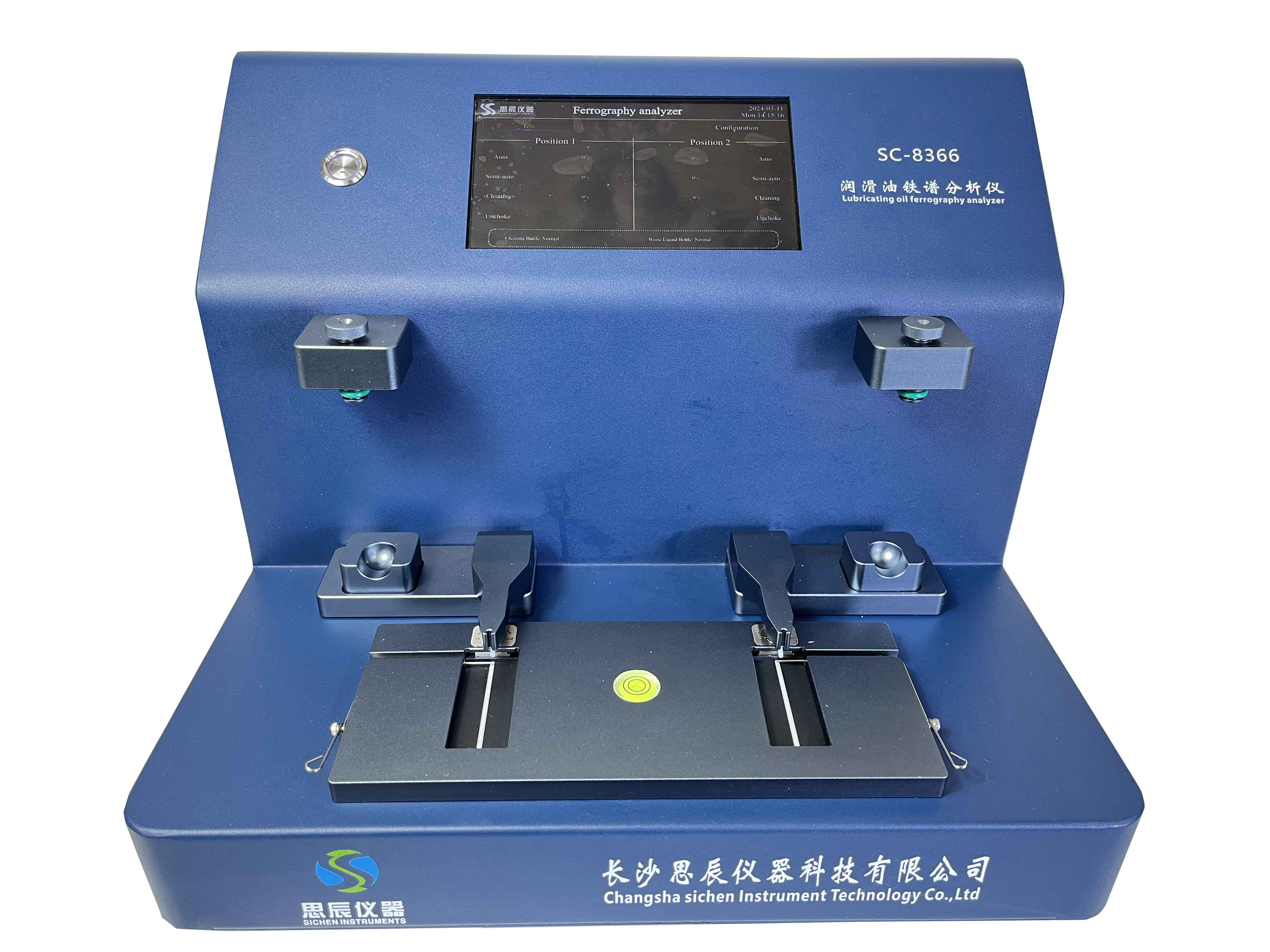

This instrument uses high gradient and strong magnetic field to separate ferromagnetic and paramagnetic abrasive particles from machine lubricating oil, and deposits them in the order of particle size on the iron spectrum plate. With the help of the iron spectrum analysis microscope, the morphology, size, composition, and quantity of wear particles can be observed and analyzed. It can be widely applied to the iron spectrum analysis and effective wear detection of lubricating oil for large machines and components such as internal combustion engines, gas turbines, gearboxes, bearings, hydraulic systems, etc. in various industries; In addition, it can also serve as a research tool for tribology and wear analysis in universities and research institutes. Statistics show that the application of ferrography analysis technology has achieved significant economic and social benefits in ensuring the safe operation of major equipment, reducing the occurrence of failures, and lowering maintenance costs.

1. Magnetic field strength: 1.5T

2. Magnetic field gradient: 5.0T/cm

3. Spectral preparation time: ≤ 20min

4. Spectral tilt angle: 2 ° to 4 °

5. Oil sample dosage: 2-3ml

6. Solvent dosage: 1-20ml

7. Solvent used: Tetrachloroethylene (analytical grade)

8. Speed control: 1-99 level speed regulation

9. Spectral specifications: 60mm * 24mm * 0.17mm

10. Test tube specification: Ø 16 mm * 100mm

11. Display screen: 240 * 128 industrial grade LCD screen

12. Dimensions: 400 mm × 385 mm × 368 mm

13. Weight: 20.5 kg

1. The patented new micro air pump is used for transporting oil samples, replacing the old peristaltic pump to achieve precise gas volume transportation;

2. The inclination angle of the iron spectrum substrate can be adjusted in stages to meet the selection of different particle size abrasive oil samples. The support arm has a positioning device that can adjust the distance between the oil pipeline and the iron spectrum substrate, keeping the inlet state of the oil sample consistent and improving the reproducibility of iron spectrum production.

3. Oil sample conveying flow rate: According to the viscosity of the oil sample, the speed can be infinitely adjusted from 0 to 99 levels to achieve precise film production.

4. Intelligent oil pipe with one click transmission to prevent pipeline blockage.

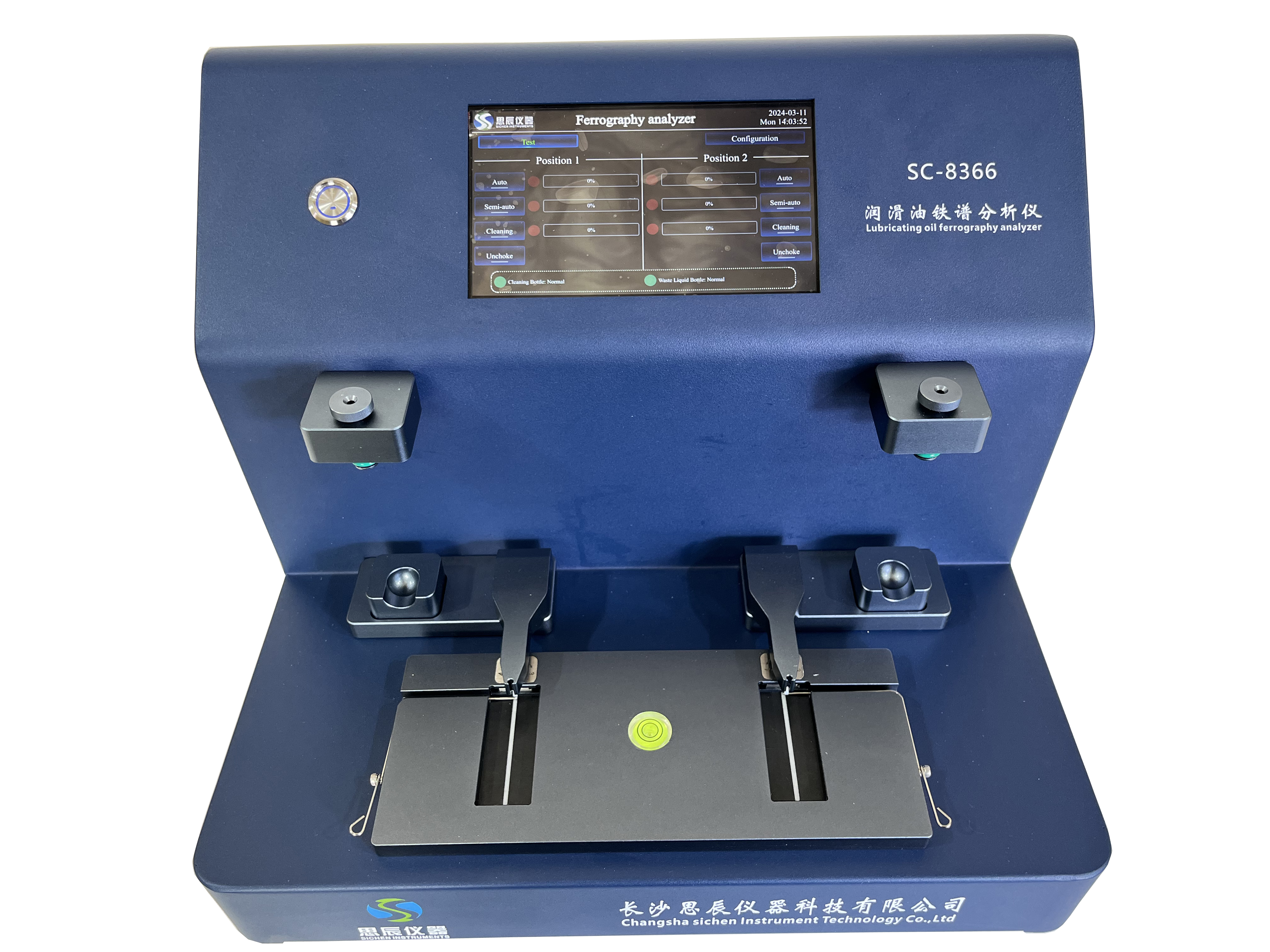

5. One click intelligent switching, can simultaneously produce two spectra, and cleaning can be performed simultaneously.

6. To ensure the normal operation of the instrument under complex conditions, maintain the stability and accuracy of the instrument, and ensure the reliability of the data, the metrology institute has issued a qualified calibration report.

7. A wide temperature resistant industrial grade LCD display screen with a resolution of 240 * 128, which has higher environmental adaptability.

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved