- Sulfur content/detection and analysis category

This instrument is designed and manufactured in accordance with the requirements of the industry standard SH/T0689 "Determination of Total Sulfur Content in Light Hydrocarbons, Engine Fuels, and Other Oil Products (Ultraviolet Fluorescence Method)" of the People's Republic of China,. Detection method: High temperature combustion UV fluorescence method for sulfur detection., Suitable for testing the sulfur content of gasoline and diesel, including National V standards. It can be widely used for the determination of crude benzene, coal tar, gasoline, diesel, lubricating oil, crude oil fractions, liquefied petroleum gas, coal gas, natural gas, plastics, petrochemical products, and other applications;

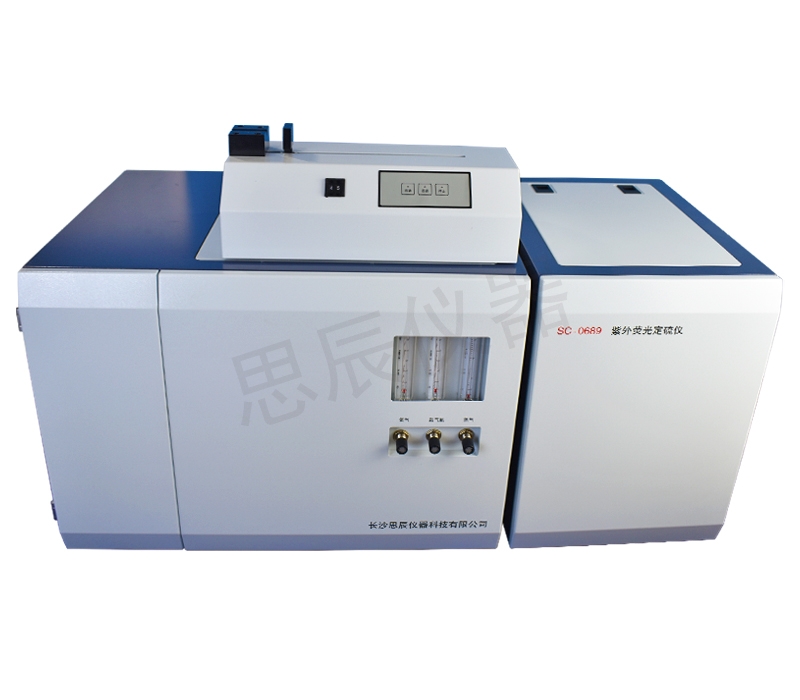

1. Power supply voltage: AC220 V ± 10%

2. Whole machine power: 1550w

3. Measurement range: 30ppb to 1%

4. Detection limit: 30ppb

5. Repetitive error:

When the content is 0.1 ppm -1.0 ppm/± 0.1 ppm

When the content is between 1 ppm and 10 ppm, it is less than 8%

When the content is greater than 10 ppm, it is less than 5%

6. Baseline drift:<2uV/72h

7. Temperature control range: Room temperature to 1150 ℃

8. Temperature control accuracy: better than ± 3 ℃

9. Cooling method: air cooling

10. Gas source requirements: high-purity oxygen: purity ≥ 99.9% high-purity argon: purity ≥ 99.9%

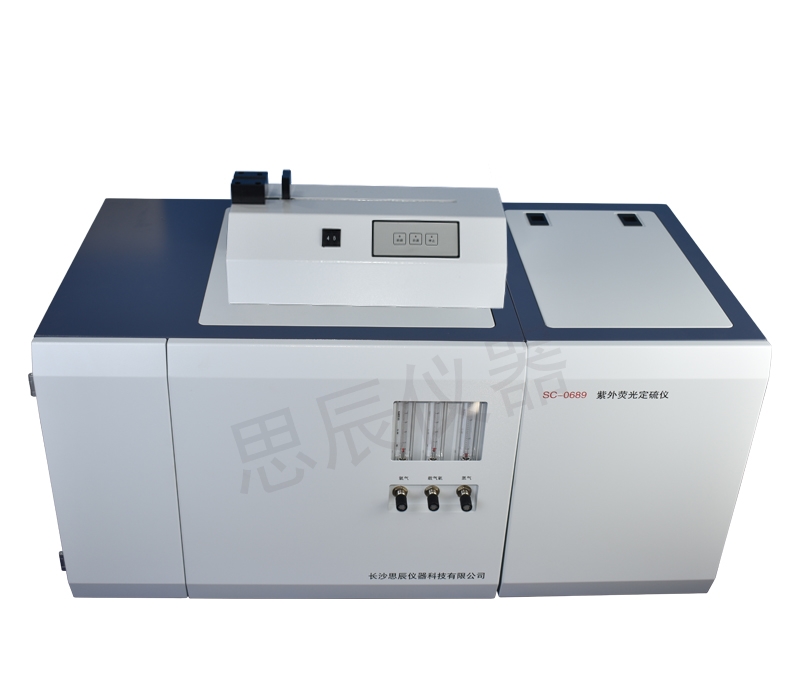

1. Widely applicable, suitable for the determination of total sulfur content in stable light hydrocarbons, light oils, or heavy oils.

2. The maximum temperature of the combustion furnace is 1150 ℃, using an independently controlled dual combustion zone method. The typical temperature of the upper combustion zone is 950 ℃, and the typical temperature of the lower combustion zone is 1050 ℃. Improved heating control results in a longer service life of the combustion furnace.

Combining single point calibration with multi-point calibration to automatically generate and save calibration curves.

3. The flow control system adopts a quality flow control system to ensure stable supply of oxygen and carrier gas. The flow rates of oxygen and carrier gas can be adjusted in the software

4. The instrument adopts a dual CPU architecture with powerful functions, stable performance, and accurate measurement results.

5. The self checking function automatically checks the gas flow rate, cracking tube temperature, etc. before the experiment to ensure the accuracy of experimental conditions, comply with experimental methods, and avoid human errors.

6. The front maintenance door facilitates maintenance and consumables replacement, including membrane dryers, ozone scrubbers, gas dryers, etc

7. 10 inch touch screen and computer dual user interface, convenient for observing the operation of the test bench and remote control from the central control room

8. Quartz cracking tubes are suitable for all sample types, filled with tubular quartz fragments to ensure full combustion of the sample inside the cracking tube and ensure the reproducibility of the experiment. The injection port of the lysis tube has threads and nuts, making it easy to replace the injection pad..

9. Equipped with a particle filter to prevent small particles from contaminating the detector and system.

10. The instrument is suitable for normal use in areas above 3650m altitude

11. Equipped with a printer to directly print analysis results and analysis charts.

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved