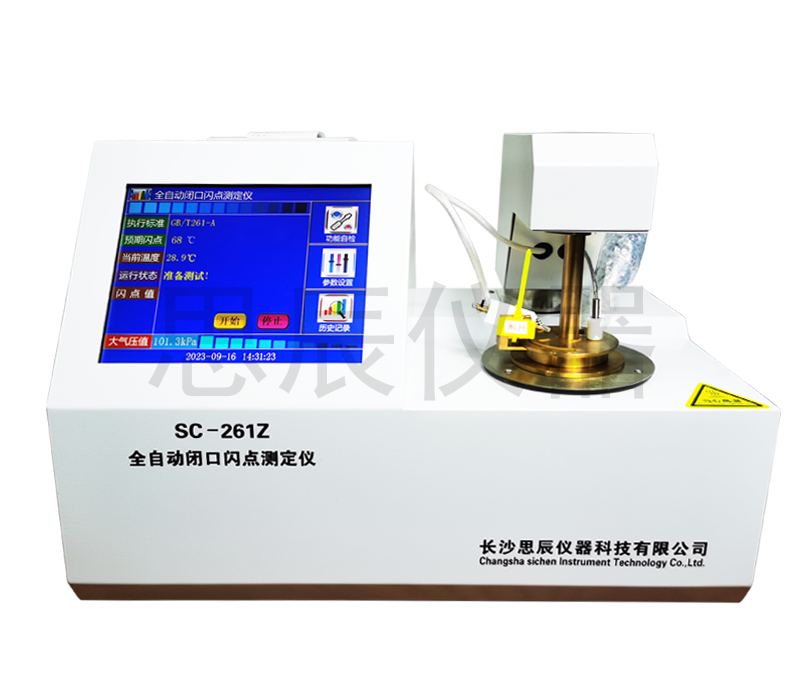

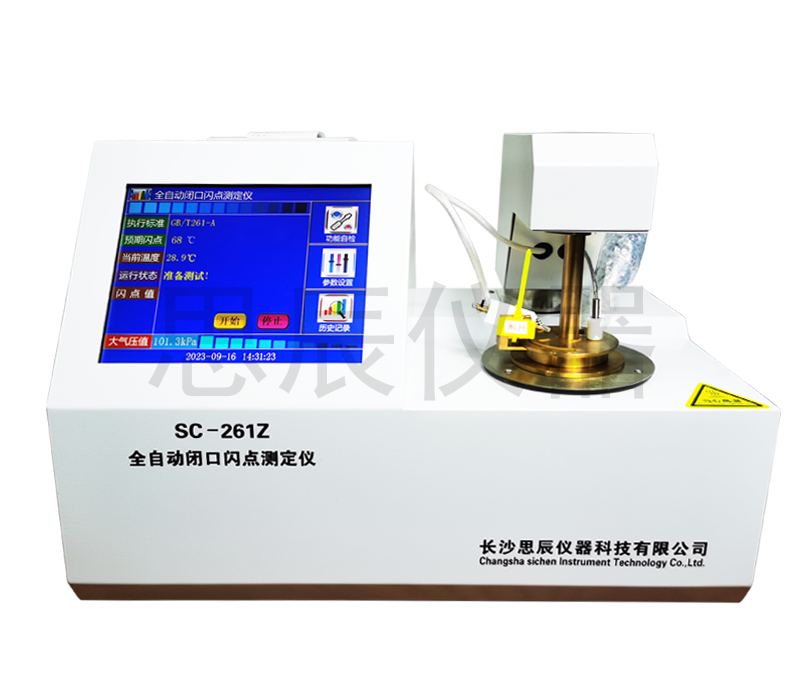

- Flash point/moisture analyzer

This instrument is designed and manufactured in accordance with the requirements of the standard ASTM D93 GB/T261-2021 "Flash Point Determination Binsky Martin Closed Cup Method". Suitable for determining the flash point of biodiesel, 0-grade diesel, liquids with suspended particles, liquids that tend to form a thin film on the surface under test conditions, and other liquids according to the method specified in GB/T261 standard. Suitable for samples with a flash point higher than 40 ℃, not suitable for liquids containing water-based coatings or highly volatile materials.

The instrument adopts AMD microprocessor technology, color touch screen, and Chinese English menu operation; The instrument has functions such as automatic ignition, flash point value display, detection and printing, and automatic cooling according to standard regulations; It has the advantages of accurate measurement, good repeatability, stable and reliable performance, and simple operation.

1. Working power supply: AC220V ± 10%, 50Hz

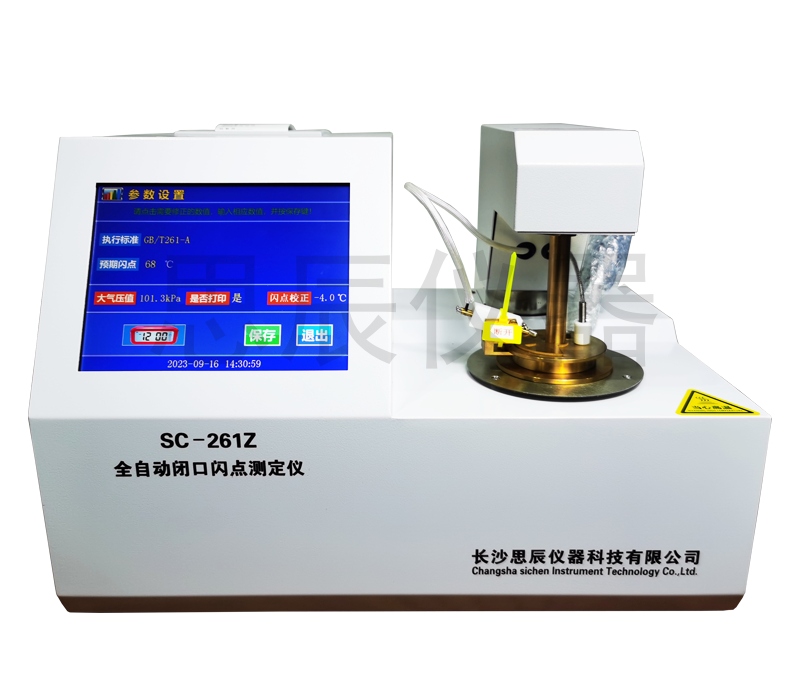

2. Execution standard: GB/T261-2008; ASTMD93;ISO2719

3. Display mode: Built in 8-inch color LCD display screen in both Chinese and English (resolution 1280X1024)

4. Operation method: Five wire resistor technology touch screen

5. Measurement range: Room temperature~400 ℃ Display accuracy 0.1 ℃

6. Temperature detection: NANMAC imported sensor from the United States

7. Flash fire sensor: ion detection ring

8. Ignition method: Electric ignition

9. Flash point detection method: Built in millisecond level ultraviolet wavelength flash point detection device

10. Cooling method: forced air cooling

11. Repeatability: superior to the requirements of GB/T261-2008 standard

12. Reproducibility: better than the requirements of GB/T261-2008 standard

13. Sample heating rate: Step A: (5-6) ℃/min

Step B: (1-1.5) ℃/min

14. Mixing speed: ⑴ (90-120) revolutions per minute, suitable for test step A

⑵ (250 ± 10) revolutions per minute, applicable to Test Step B

15. Power: < 500W

1. By adopting unique Peltier protection technology and automatic ignition cleaning program, the performance and lifespan of the temperature control device have been optimized, and the ignition device and testing accuracy have been efficiently protected.

2. Using high-precision processors imported from AMD, the PID control algorithm has high sensitivity and automatically adjusts the heating curve according to standards.

3. The entire experimental process of detection, lid opening, ignition, alarm, cooling, and printing is automatically completed.

4. Safe without gas source, platinum alloy electric heating wire ignition method, safe, stable, reliable, high testing accuracy.

5. Built in atmospheric pressure automatic detection chip, automatic measurement, calibration and correction of atmospheric pressure, and automatic correction of flash point value.

6. Differential detection, automatic correction of system deviation, automatic stop detection and alarm for temperature exceeding the limit.

7. Powerful storage function, capable of storing 500 measurement results for convenient historical queries.

8. Intelligent computer control, heating, opening, ignition, detection, printing, storage during flash point detection process, automatic completion of experimental testing process

9. Satisfy normal use in areas above 3650m altitude

10. Uniform heating block in the electric heating area, with a testing method or user-defined heating rate ranging from 0.5 to 12 ℃/min.

11. Intelligent Pt100 probe internal calibration, glass Pt100, temperature range -50 ℃ to+450 ℃, resolution 0.1 ℃.

12. Automatic mixing, ranging from 0 to 300 RPM according to testing methods or customer customization.

13. The intelligent electric igniter and automatic power management have a long service life testing method or user-defined testing interval ranging from 0.5 ℃ to 5 ℃.

14. The built-in pressure sensor automatically corrects the flash point, and the pressure units can be set to mbar, hpa, kpa, mmHg, or Torr.

15. The unique hot flash point detection can detect all types of flash points.

16. Not less than 7 inches color touch screen, alphanumeric input, barcode reader.

17. Store no less than 500 results, 200 products, user-defined printed result reports, and customized LIMS protocols.

18. Ethernet or RS232, using defined data strings, automatically LIMS transfers data export: USB, import to Excel.

19. Automatic QC - Sample Processing and QC Icon. Operators with different access levels, service or laboratory managers.

20. User defined calibration cycle, automatic diagnostic function can automatically detect or violate safety regulations, and users can choose experiment termination or alarm information.

21. The built-in fire sensor detects fires or flash fires outside the cup, and the fire extinguishing system can be connected to external inert gases (nitrogen or carbon dioxide).

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved