- Distillation/distillation range/pour point category

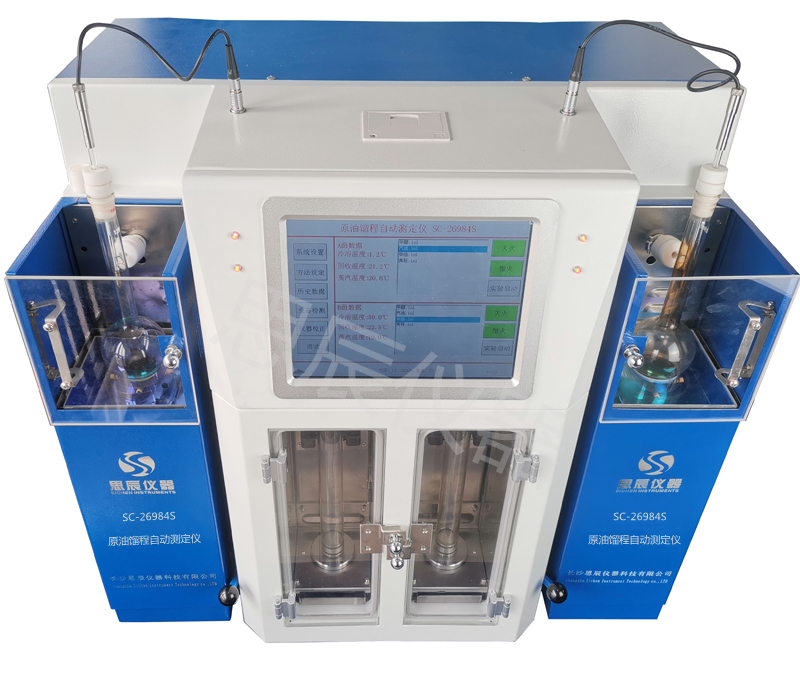

This instrument is a third-generation product newly developed by our company, designed and manufactured according to the national standard GB/26984-2011 "Determination of Crude Oil Distillation Range" standard test method. It integrates mechanical, optical, and electronic technologies, using imported sensors. The volume reading of the graduated cylinder recovery adopts an imported CNC precision optical tracking and detection system. Automatically complete the entire distillation process experiment, widely applicable for the determination of crude oil with a water content mass fraction of no more than 0.2%. For crude oil with a water content mass fraction greater than 0.2%, dehydration treatment is also required to adapt. It is possible to conduct testing experiments on two sets of samples simultaneously, greatly improving work efficiency

1. Working power supply: AC220V ± 10% 50Hz 1.6KW

2. Operation method: Windows operating system 10.4-inch color LCD touch screen

3. Temperature range: 0-450 ℃, resolution 0.1 ℃, PT100 temperature sensor imported from Germany

4. Refrigeration method: German imported compressor refrigeration

5. Distillation rate: 2-10 mL/min (freely set, automatically adjusted)

6. Volume detection range: 0-100mL resolution 0.1mL

7. Cold bath temperature range: 0-80 ℃, temperature control accuracy of 0.2 ℃

8. Cold trap temperature range: 0-60 ℃, temperature control accuracy of 0.2 ℃

9. Pressure measurement range: 300-1100hPa, accuracy ± 3hPa, built-in pressure sensor, automatic value adjustment

10. Safety protection system: Built in ultraviolet flame sensor for automatic monitoring, automatically opens the protective air valve when a flame occurs

11. Protective gas interface: diameter 7.5-8mm; The protective gas is nitrogen or carbon dioxide, with a pressure not lower than 0.6Mpa

12. Instrument dimensions: 460X500X660cm (length/width/height), net weight: approximately 70 kilograms

13. Operating environment temperature: 5-40 ℃ Operating relative humidity: ≤ 80%

1. The temperature of both the cold bath and the cold trap is controlled by a segmented program. The cold bath part adopts a metal bath technology that integrates condenser tubes and refrigeration evaporation tubes, ensuring direct conduction of cold and heat without liquid heat transfer medium, which is both safe and convenient

2. The instrument adopts a lifting and self-locking lifting control technology, and the heating furnace can be quickly raised and lowered, and can be stopped at any position, truly realizing non-polar adjustment technology. At the end of the experiment, the furnace frame automatically slides down, cutting off the residual heat of the heat source and achieving rapid cooling

3. The heating furnace adopts ceramic heating device pulse modulation infrared radiation heating method, with fast heating and cooling speed, ensuring safety and reliability

4. The compressor, heating ceramic element, temperature sensor, and refrigeration diversion valve all use imported components to ensure the accuracy and reliability of instrument data, while also having a long service life and low failure rate

5. Unlimited storage of experimental data and real-time viewing, with built-in micro thermal printer outputting detection results

6. Electric furnace cooling, after the experiment is completed, the cooling fan can automatically start and quickly cool down

7. Infrared modulation optical technology realizes liquid level tracking detection and initial distillation detection, which is not affected by environmental interference, automatically detects the zero position of the volume, and can accurately determine the dry point

8. Coated quartz orifice plate, heat-insulating and non explosive, easy to install orifice plate structure, no need to adjust when replacing orifice plates with different diameters

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved