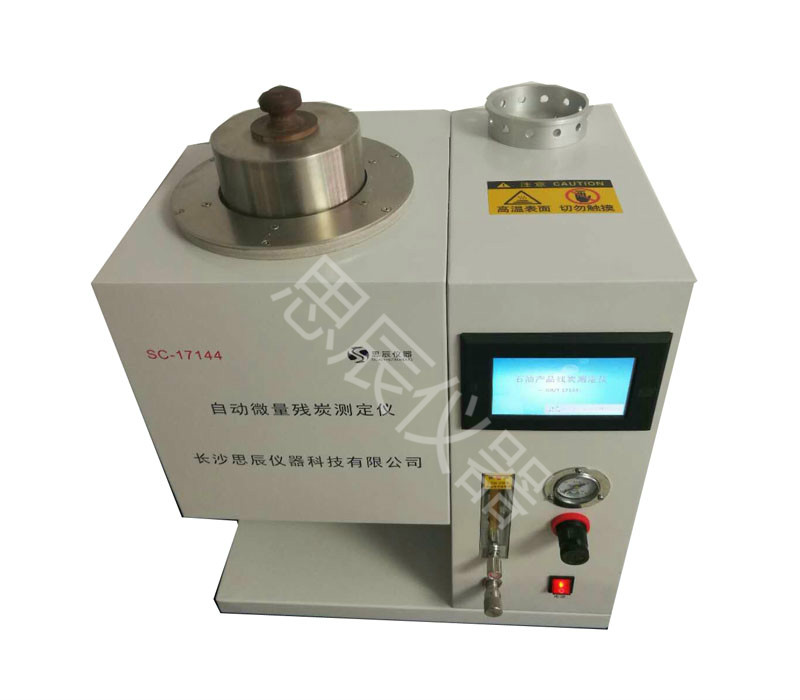

- Determination of vapor pressure/residual carbon

This instrument is designed and manufactured according to the standard GB/T 17144 "Determination of residual carbon in petroleum products (micro method)" of the People's Republic of China. It is suitable for determining the residue formed by the sample after evaporation and pyrolysis in accordance with the requirements of GB/T 17144 standard. The measurement results are equivalent to the results of the Kang style residual carbon measurement; It is also suitable for detecting petroleum products composed of distillate oil with a residual carbon value below 0.10 (m/m).

1. Working power supply: AC220V ± 10%, 50Hz

2. easurement range: 0.10% (m/m) -30.0% (m/m)

3. Temperature range: Room temperature -500 ℃

4. Heating rate: 10-15 ℃/min

5. Constant temperature accuracy: 500 ℃± 2.0 ℃ constant temperature for 15 minutes

6. Set time error:<0.1s

7. Temperature display: LED ≥ 4 digits

8. Pressure regulation range: 0kPa (0kg/cm2) -392kPa (4kg/cm2)

9. Combustion chamber size: Φ 85mm × 105mm

10. Waste liquid collection bottle: 200ml

11. Heater power: 1000w

12. Dimensions: 230 × 320 × 425mm

13. Gas inside the furnace: N2 gas (flow rate of 150ml/min and 600ml/min; can be automatically switched)

14. External N2 gas source: The input pressure should be between 0.3-0.4Mpa

15. Gas consumption: A standard nitrogen cylinder with a pressure of 14700kPa (150kg/cm2)

1. Touch the LCD screen to display the combustion chamber temperature, heating rate, running time, status, etc. of the instrument, and display the temperature curve in real time..

2. Equipped with fault self diagnosis and automatic alarm functions; It has the function of calculating experimental results and can calculate repeatability and reproducibility.

3. Real time display of the instrument in a certain state of "blowing", "heating", and "constant temperature".

4. Editable input of sample tube and sample quality, automatic calculation of residual carbon value.

5. Can store 100 sets of historical data for easy querying. Historical data can be queried based on dates.

6. Satisfy normal use in areas above 3650m altitude

7. Equipped with stabilizing and stabilizing devices, the flow control is more stable and automatically switches.

8. It has a status display function and can measure no less than 12 samples.

9. Scalable installation of LIMS interface for transmitting test data.

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved