- Other/Petroleum Product Testing Category

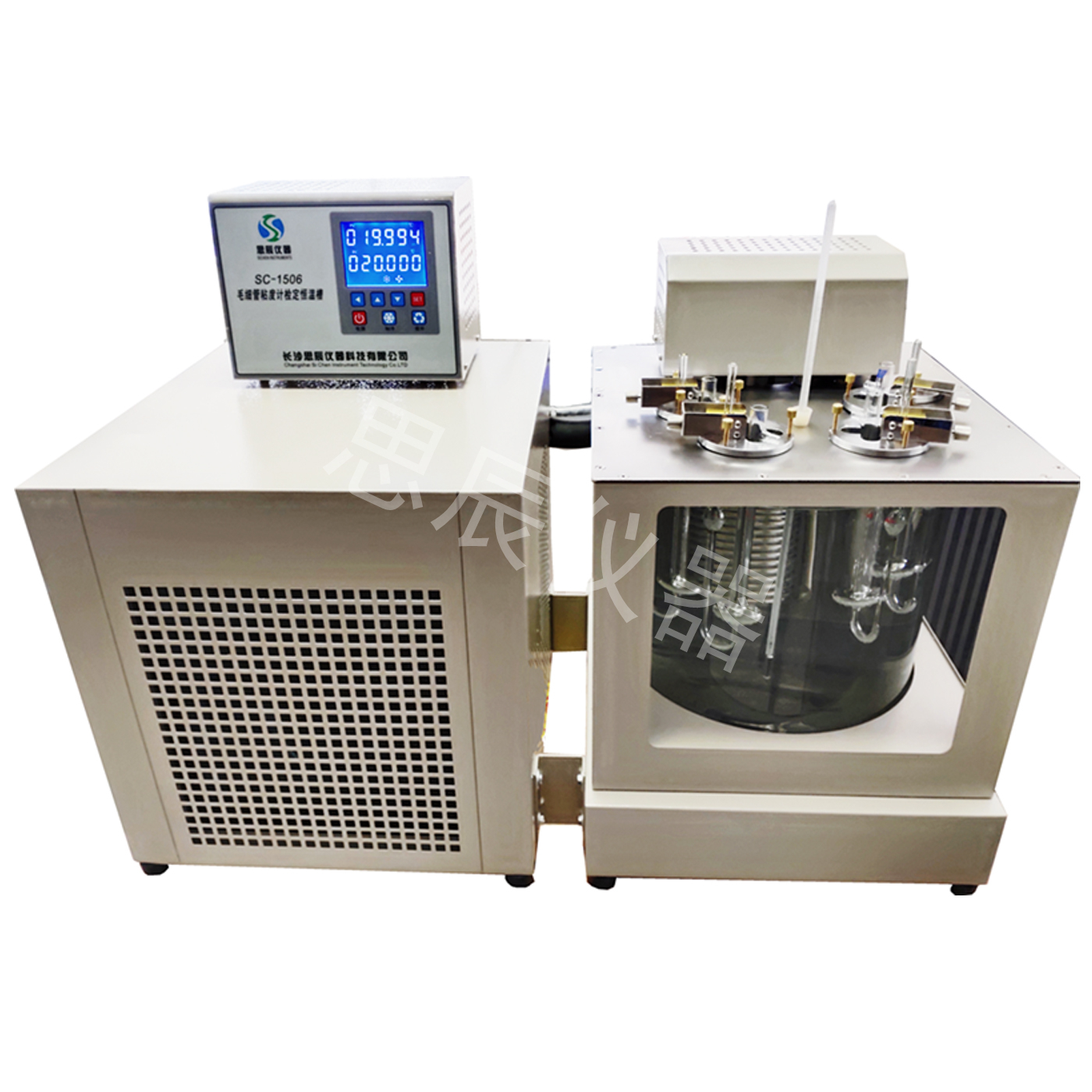

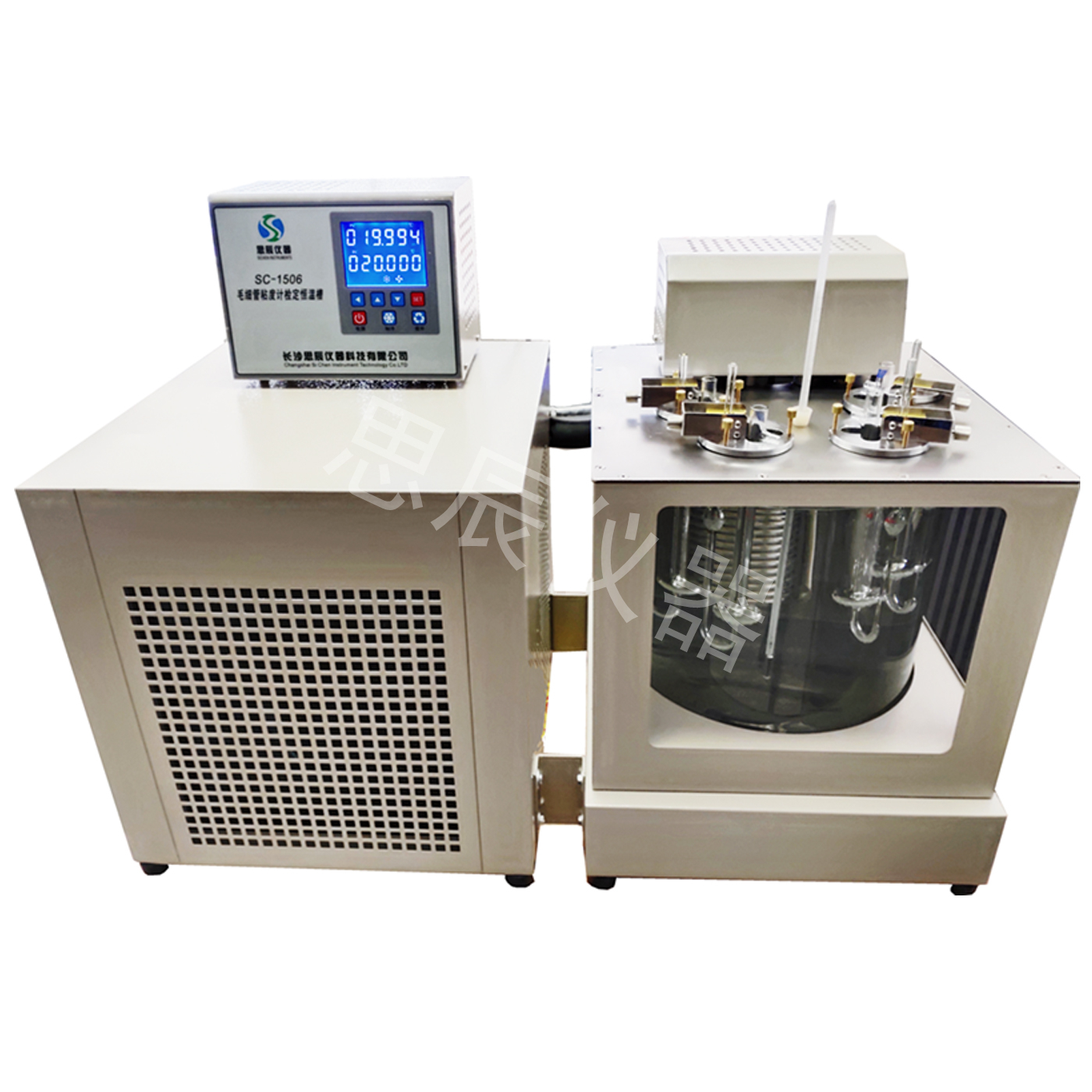

This instrument is a new type of equipment developed and produced by our company according to the requirements of the national JJG155-2016 verification regulations for capillary viscometers used in work. It is controlled by a single-chip intelligent instrument meter. Equipped with a viscometer fixture, it can hold 4 capillary viscometers at once, widely used for the calibration and measurement of working capillary viscometers such as Ubbelohde, Heisei, and Fischer, as well as other physical and chemical experiments. The capillary viscometer calibration constant temperature bath is suitable for research departments such as petroleum, chemical, electronic instruments, physics, chemistry, biotechnology, medicine and health, life sciences, light industry and food, physical property testing and chemical analysis, universities, enterprise quality inspection and production departments. Especially suitable for the calibration and measurement of working capillary viscometers such as Ubbelohde, Heisei, and Fischer.

1. Working power supply: AC220V ± 10%, 50Hz

2. Temperature control range: adjustable from 10 to 100 ℃

3. Digital display resolution: 0.001 ℃

4. Temperature fluctuation: ± 0.005-0.01 ℃

5. Working groove depth (mm): 300

6. Working slot opening size: Ø 65

7. Power: 2.2kw

8. Instrument size (mm): 810 * 450 * 430

9. Environmental temperature: 0 ℃~35 ℃

10. Relative humidity: ≤ 85%

1. Adopting temperature control technology with temperature field compensation, equipped with high standard PT100 and fully imported electronic components.

2. The software system facilitates the correction of errors between displayed temperature and actual temperature, with a temperature correction resolution of 0.001 ℃, ensuring accurate and error free display of temperature values.

3. It has over temperature protection, over temperature alarm, and can set over temperature alarm temperature. When over temperature occurs, the load can be automatically cut off.

4. Intelligent software has strong temperature stability, and PID can automatically adjust parameters according to different media. Special users can also manually readjust parameters.

5. Use software to digitally lock the set values of the control system to prevent unauthorized personnel from operating and ensure the accuracy of experimental data.

6. The refrigeration system adopts an imported air-cooled fully enclosed compressor unit with multiple protections against overcurrent and overheating.

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved