- Distillation/distillation range/pour point category

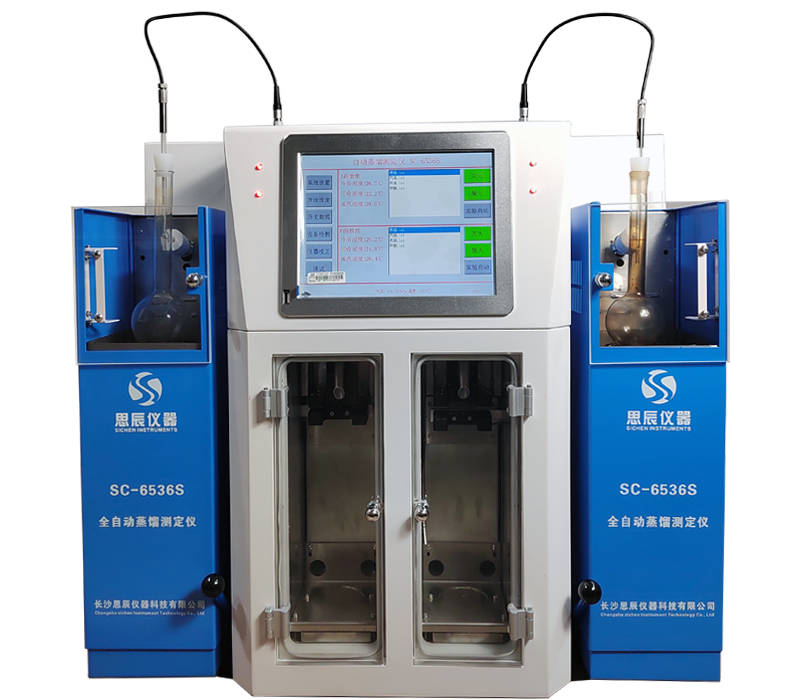

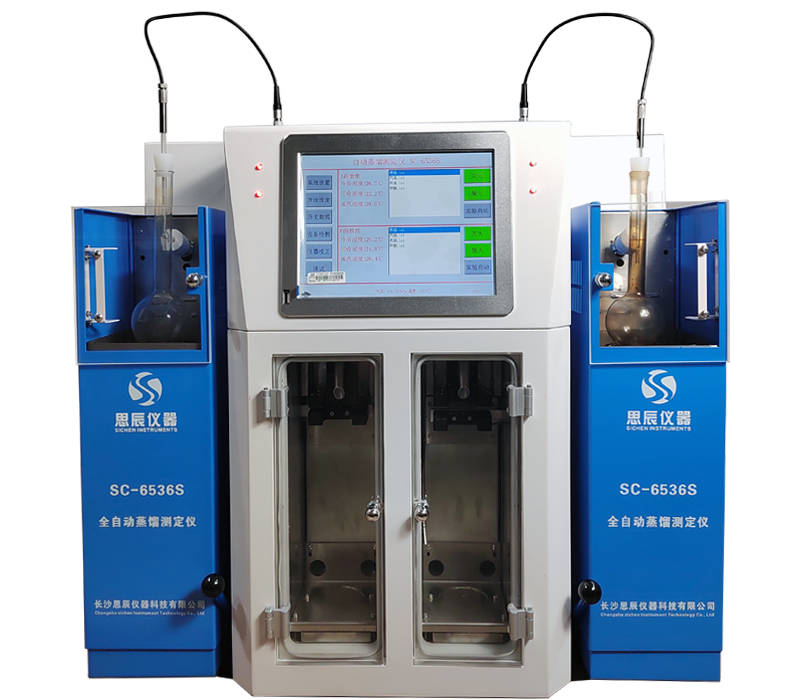

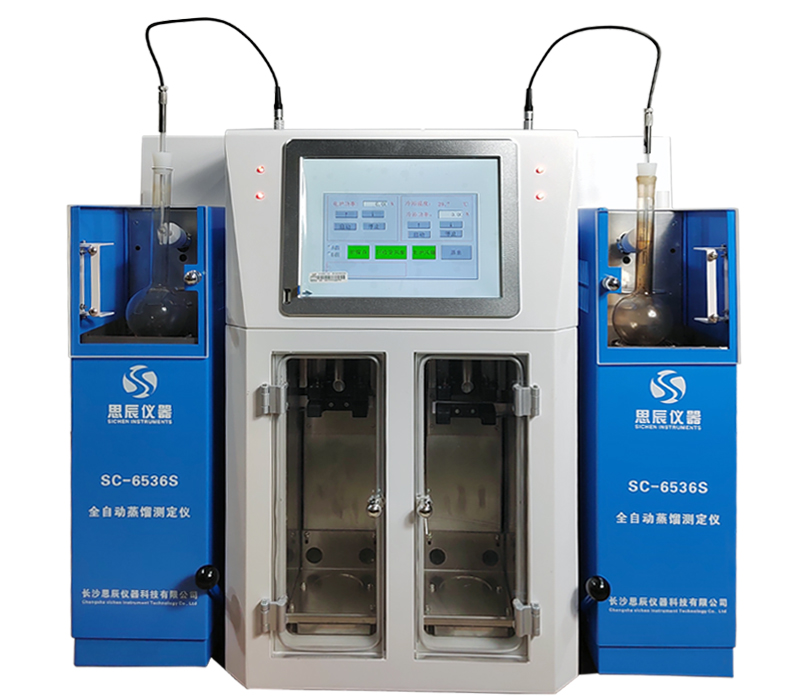

This instrument is the latest third-generation product developed by our company. It is designed and manufactured according to the national standard GB/T6536-2010 "Determination of Atmospheric Distillation Characteristics of Petroleum Products" standard test method, and can measure two samples simultaneously. It can meet international standards such as GB/T3146-2010 "Determination of Distillation Range of Industrial Aromatic Hydrocarbons and Related Materials - Part 1 Distillation Method" and ASTM D86/ASTM D850/ASTM D1078-IP195/ISO3405. It integrates mechanical, optical, and electronic technologies, uses imported sensors, and adopts imported CNC optical tracking detection system for measuring cylinder liquid level reading. Automatically complete the entire distillation process experiment, widely applicable for measuring and analyzing the distillation characteristics of distillate fuels such as natural gasoline (stable light hydrocarbons), light and middle distillates, automotive spark ignition engine fuels, aviation gasoline, jet fuel, diesel and kerosene, as well as naphtha and naphtha solvent oil products under normal pressure.

1. Display interface: 10.4-inch color LCD touch screen, capable of Chinese character input, parameter setting and analysis interface can be displayed in one interface, with simple and fast operation.

2. Temperature range: 0-500 ℃, resolution of 0.1 ℃, measuring element PT100 (imported from Germany).

3. A lifting control device that can enhance self-locking - patented technology

Adjustable lifting capacity of heating furnace: ≥ 35mm

4. Teflon specific connectors and locking sleeves - sealing and positioning

5. Unrestricted methods and data storage

6. Coated quartz orifice plate, heat-insulating and non explosive, unique orifice plate installation structure, no need to adjust the position when replacing orifice plates with different apertures.

7. Volume detection: Measurement range: 0-100mL, resolution: 0.1 mL.

8. Distillation rate: 2-10 mL/min (freely set, automatically adjusted), using fuzzy control algorithm to adapt to various samples, and the rate meets experimental requirements.

9. Output method: Embedded micro thermal printer.

10. Cooling method: Compressor cooling, maintenance free (imported Danvers brand). Refrigeration is achieved by quickly and automatically adjusting the evaporation rate of refrigerant through regulating valves.

11. Temperature control range of condenser: 0-60 ℃

12. Temperature control accuracy: ± 1 ℃

13. Using quartz flask and quartz measuring cylinder.

14. Overall power: 1.6Kw

15. Operating environment temperature: 10-40 ℃.

16. Relative humidity: ≤ 80%

1. The instrument can test two samples simultaneously, and the parameters can be set on the 10.4-inch color LCD touch screen interface, truly achieving dual tube operation on one machine; The operating system is located on the front of the instrument, making it convenient for users to operate

2. Cold bath control: temperature range of 0-80 ℃, temperature control accuracy of 0.2 ℃. The heating rate of the cold bath can be controlled by segmented programs to ensure reliable condensation and outflow of light and heavy components during the distillation process. The cold bath adopts patented technology of integrated cold and hot conduction condenser, which enables fast and efficient cold and hot conduction of the instrument, without liquid conduction medium, and is safe and convenient. Adopting an internal circulation method, there is no need for water bath cooling to avoid leakage and freezing, which is safe and energy-saving.

3. The instrument is suitable for normal use in areas above 3650m altitude

4. Automatic temperature control, eliminating the need for measuring cylinder baths, pressure irons, and cushion blocks, making operation more convenient.

5. Cold trap control: temperature range 0-60 ℃, temperature control accuracy 0.3 ℃, temperature inside the cold trap can be controlled by segmented program, fully enclosed independent space.

6. Pressure detection: measurement range of 300-1100hPa, accuracy of ± 3hPa, built-in pressure sensor. Automatically adjust the sample temperature value.

7. After the sample is completed, automatic flame testing ensures the safety of the laboratory;

8. The heating furnace adopts ceramic heating device pulse modulation infrared radiation heating method, with fast heating and cooling speed, ensuring safety and reliability;

9. Infrared radiation heating with a reflective cover greatly improves thermal efficiency, reduces thermal energy loss, and can save energy consumption by 40%. At the same time, it provides good thermal protection for various components below the furnace wire, extending its service life;

10. The heating furnace frame can be manually lifted to any position and can be manually slid down quickly and flexibly. When the experiment is over, the furnace frame automatically slides down, cutting off the residual heat of the heat source and achieving rapid cooling;

11. Electric furnace cooling, after the experiment is completed, the cooling fan rapidly cools down.

12. The built-in UV flame sensor automatically monitors and opens the protective air valve when a flame occurs, ensuring the safety of the experiment

13. The compressor, heating ceramic element, temperature sensor, cooling fan, and cooling diversion valve all use imported components to ensure the accuracy and reliability of instrument data, as well as long service life and low failure rate.

14. The connection of the distillation flask branch pipe and the installation of the temperature sensor both have patented technology fixed plugs, which are convenient and simple to use, with good sealing and consistent sensor positions.

15. Infrared modulation optical technology realizes liquid level tracking detection and initial distillation detection (imported from Panasonic), which is not affected by environmental interference and automatically detects the zero position of the volume.

16. Can connect and transmit data to LIMS system;

Tiktok

Video

Mobile website

Copyright (C) Changsha Sichen Instrument Technology Co., Ltd. 2024 All Rights Reserved